UW video casing by Bernd Zoll

back to homepage | back to other peoples projects

email: Bernd Zoll

The original graphic has a higher resolution as displayed here. Click at the picture for the original version (54KByte).

The pipe is to big actually, but to get the suitable size I would have to buy a piece of 5meter (about € 250,-).

A

friend machined off the endings with a lathe (flat, without groove).

A

friend machined off the endings with a lathe (flat, without groove).

The panes are made of Perspex. I think holes in real glas would crack and they are expensive to drill.

The sealing is made of ordinary silicone (hardware store). A form of sausage is sprayed onto an even base, two pieces of foil below and above. Then press the pipe onto the sealing to get a flat form. Take the pipe away and let the sausage dry, cut the edges, ready. The foils are weted with sopa water to seperate them easily.

The thread rods are at the outside. Not quite nice but without any sealing problems.

I first planned to close the body with spring-loaded clamps, but here

far away from a big city, no parts of stainless steal were available. The

bolts of the wings are screwed into beat-in-nuts.

I took apart the camera and fixed thin wires at the most important keys.

The wires are lead to a wide plug. From there a multi wire cable goes to

the reed contacts and the additional circuit board.

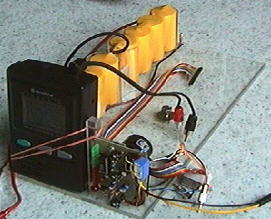

The

additional circuit gives a battery voltage control, water sensor (which

even senses high humidity) and a circuit that switches on the LC-Monitor

when the camera is on. As electrical engeineer I enjoyed this part (therefore

the changes at the camera).

The

additional circuit gives a battery voltage control, water sensor (which

even senses high humidity) and a circuit that switches on the LC-Monitor

when the camera is on. As electrical engeineer I enjoyed this part (therefore

the changes at the camera).

The

complete setup with camera, accu, monitor and circuit is fixed at a Persplex

plate which is completely pushed into the body, connect reed contacts,

ready.

The

complete setup with camera, accu, monitor and circuit is fixed at a Persplex

plate which is completely pushed into the body, connect reed contacts,

ready.

The magnet for the reed contacts hangs at a strap around the body at the moment, but in the future it will be built into a glove.

Much later a solution with microcontroller and reflected light barrier is planned. The conroller can also measure depth and temperature, calculate a diving profile and show it at another LC-display. An outside microphone is another problem.

Because I didn't have much time lately for diving, I couldn't test for

pressure resistance.

Technical data:

- 495mm wide

- weight: 14-15kg

- positive buoyancy about 100g

- tube:

- length: 340mm

- outer diameter: 225 mm

- inner diameter: 200mm

- glass thickness: 10mm

- thread poles: 4mm

- wing thickness: 5mm